Manufacturing Resource Planning

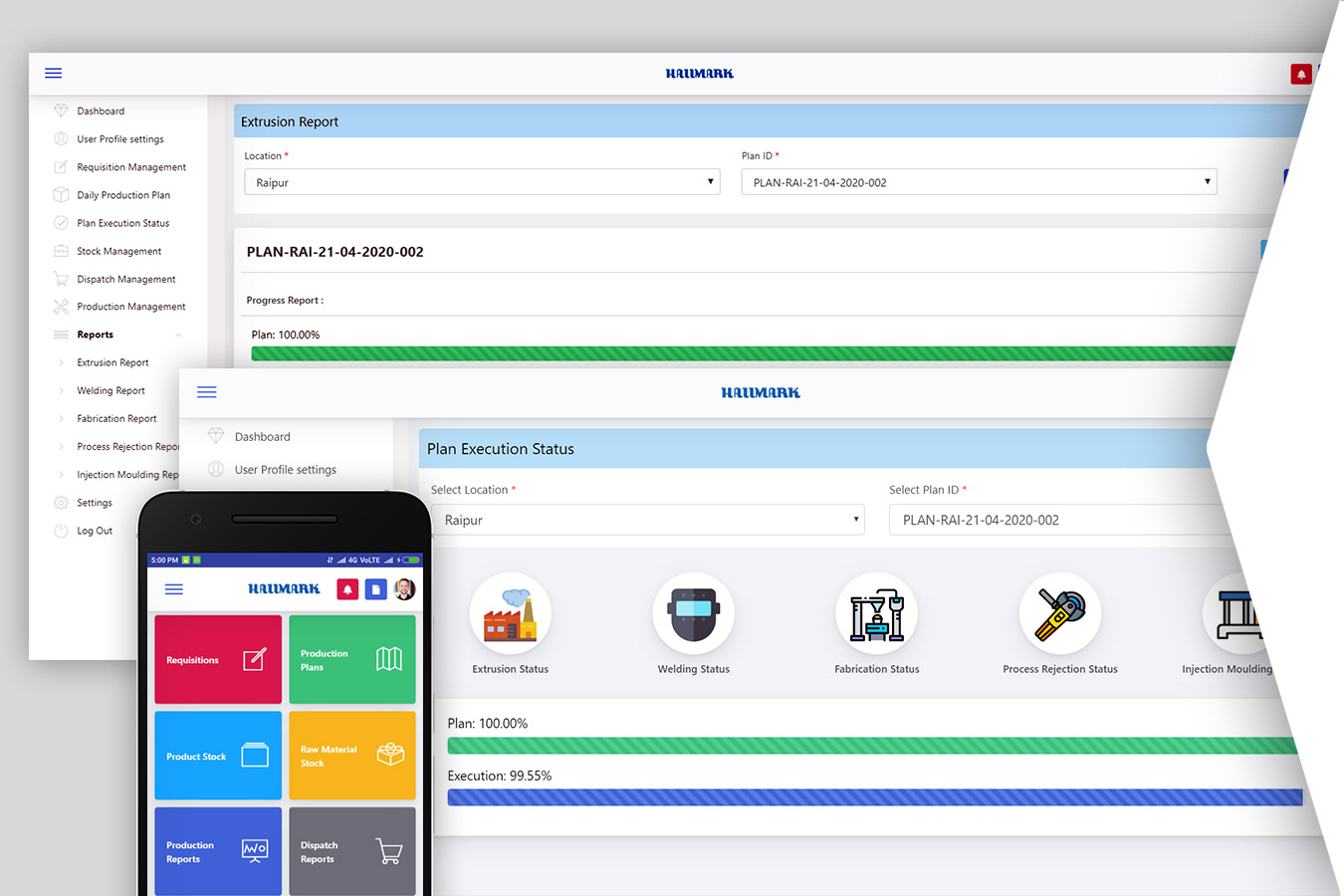

(A Progressive Web Application)

A Manufacturing Company based in India contacted us as they wanted something to maximize production efficiency, increase real-time visibility, enable business growth, and accelerate business digitalization.

It was an interesting project because we needed to digitize, automate, and optimize a workflow which got established in the last 27 years by the client company. As a part of our standard scoping exercise, a team of Business Analysts went to the manufacturing units to scope every area of improvement, automation & and digitization and started giving the shape of it. Blue Copper made the client company almost paperless & and more importantly people are now able to get out from creepy spreadsheets with hundreds of columns and different formats. Their turnaround time has dropped in minutes which used to take hours.

We were indeed able to add value to their business as a technology consulting company, which is allowing us to return business. We are about to start another project with them.

Technology Used :

Industry : Manufacturing

Manpower : 200+

Location : India

Quality Index = 4.8

C S Index = 5.0

What Client Said

The Application really helped us a lot. It has reduced the presales time span by 75% and made the overall manufacturing process much smoother & easier.

- General Manager, Manufacturing Company

Key Challenges

- The scope was to Digitize, Track, and Optimize an entire Manufacturing company that was running on Paper and Spreadsheets.

- The client operation team was not computer savvy.

- The entire solution was to be very easy and self-motivating in terms of UI/UX.

- Every aspect was to be covered right from Procurement to Production and supply.

- The customer was dealing with lots of exceptions and revenue leakages that needed to be patched.

Our Solution

- We proactively offered them a plan to build one PWA application that can be used on various mobile devices as well as desktops and Laptops.

- This was done strategically since in the manufacturing domain data entry happens from remote sites which requires mobility in the application.

- We started scoping the entire manual process which was in place and made it streamlined so that it could be automated.

- Data modeling was focused mainly on retaining all information to make the application intelligent.

- We also included various approval & and notification methods.

- Management Reporting and KPI were the major areas of development.